Barrel Aged Stouts and Charred Oak

Let’s talk about an interesting topic: Barrel-aged beers. I started thinking hard about these after I just paid $9.99 for a 16oz bottle of Bourbon County Stout this Black Friday. It got me thinking: I’m a competent homebrewer, I’ll just crank out a batch and age it myself. Experience making high gravity beers: Check. Tasty RIS recipe: Check. Barrel-aging: Um, not so much. And there lies the sticky point: Barrel aging. It’s something home brewers struggle to replicate short of getting together with a club, buying a barrel, and brewing 55-60 gal to fill said barrel. I personally have little to no experience with it. I’ve oaked a few beers before, but none had anything close to what I would call “barrel-aged” flavor.

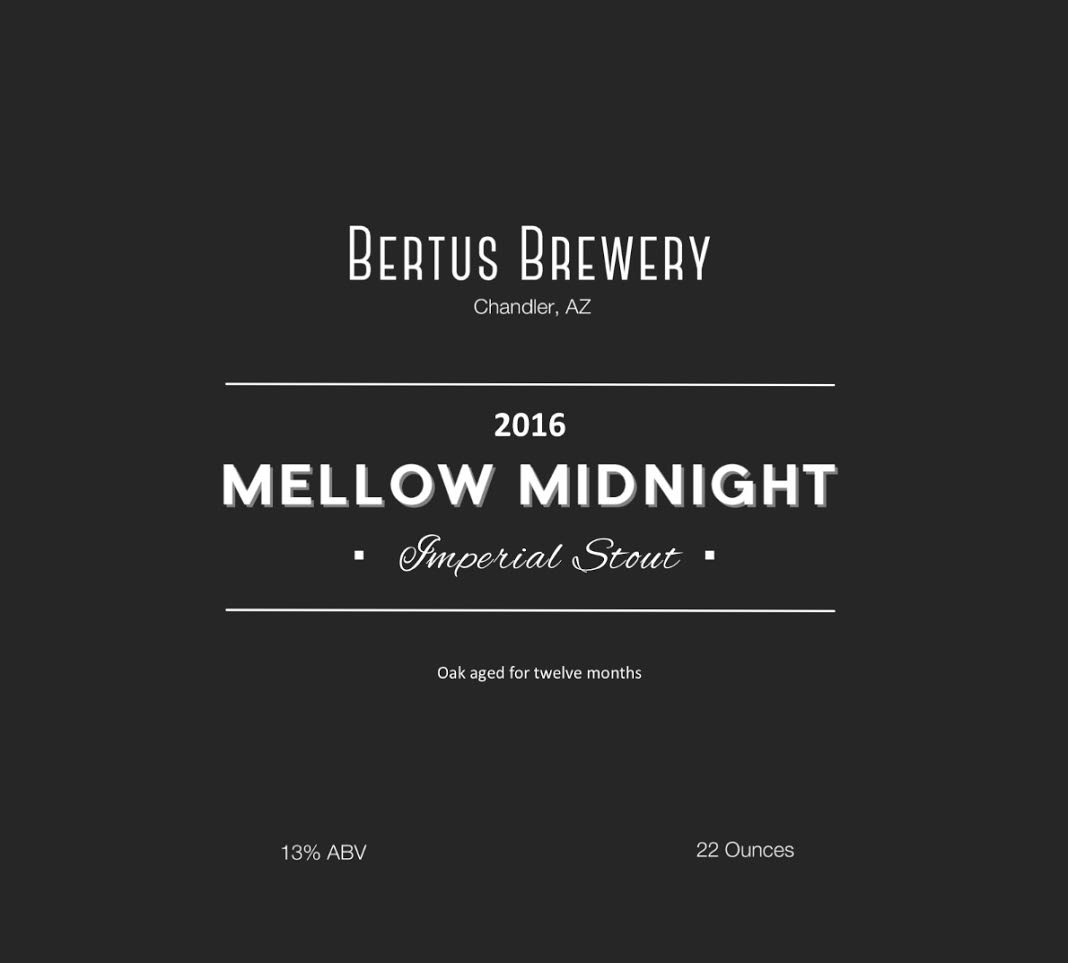

So I’ve spent the last weeks putting a few things together. First, a recipe for a 12-13% ABV Imperial Stout that will serve as the base beer for many adjunct-filled adventures over the next few years. Second, a plan for starting a home-brewed vertical of my own, including some sweet labels. The plan is to brew a barrel-aged stout once a year, then age it for a full year. Each year’s batch will get a different adjunct (vanilla bean, coffee, chocolate, etc). Next, I went ahead and brewed that recipe for the massive Imperial stout over the weekend. It’s fermenting away happily (read:vigorously) right now. Lastly, and most importantly, I’ve spend a lot of time thinking about just how the hell can we recreate barrel aging at the home brew scale.

Let’s first talk about what the status quo seems to be for replicating bourbon barrel-aged flavor at home. Buy some toasted oak cubes, toss them in some bourbon for awhile, then add them to the beer for another length of time. There’s a few variations to this method, but most seem to follow that script. The issue is, it just doesn’t re-create that barrel aged flavor commercial examples have. Also, we end up having to add large amounts of bourbon (4-12oz) to get a noticeable effect. That is order of magnitude more than a barrel-aged beer picks up from the barrel. There’s got to be another way to do this. Used barrels are expensive and just too big. New 5-gallon ones are available, but new barrels present their own problems.

The issue of oxidation, or lack of, is something that many advanced homebrewers have made some headway on. From using oak dowels, to aging in plastic buckets, there seems to be a few clever methods to slowly allow O2 into a beer while aging. I’d actually like to hear if anyone has experience with these methods. I’m not going to focus too much on the oxidation topic today. As of right now, I’m planning to vent the headspace of the keg (pulling the release valve for a second) once or twice while the beer ages.

The issue of replicating that bourbon barrel flavor is what I’d really like to talk about.. I’ve literally spent the past couple weeks thinking long and hard about what we’re missing at the home-brew scale. I’ve scoured the internet as well, but didn’t find much. I know batch sizes and surface area make a difference, but they can’t have that much of a difference. So why is it that real barrels create the effect we’re looking for, but oak cubes and bourbon can’t?

Finally a eureka moment hit. I’ve seen videos showing how whiskey barrels are made. They’re charred black like charcoal on the inside under intense flames. The oak cubes we use for brewing are merely toasted. Could that be the difference? Well toasted oak cubes were designed to replicate wine barrels, as the wine industry uses toasted oak barrels rather than charred ones. So I did some searching to see if anyone was talking about using charred oak in beer, and there doesn’t seem to be anything meaningful. I finally stumbled across a four year old post post on HBT where KingBrianI tested the differences between toasted oak and charred oak in moonshine. Now feeling like I was onto something, I thought maybe the home distillers have thought of this. I searched “distilling oak char”, and BOOM. Turns out our brothers on the illegal-side of the fence have done quite a bit of research on the topic. They face the same dilemma we do, in that toasted cubes seem to be the only product readily available on the market short of buying a new barrel. So many of them char their own oak using MAPP, propane, or oxy-acetylene torches. There’s a very detailed post on the artisan distiller forum experimenting with just this topic. The person found the charred examples had more ‘bourbony’ character to un-aged whiskey than toasted oak did. Maybe the answer is right in front of us; we’re using the wrong oak.

So what’s my plan? Well I’m not entirely sure, as I don’t have experience with any of this. Anything I try is just going to be a shot in the dark. I do feel like I’m onto something here though, so shoot in the dark I will. As for right now, I’ve got a giant Imperial Stout (1.118) cranking away in the primary. I’ll post some recipe details here in about 2 weeks once it’s ready to go down for a year long-nap in the keg.

I purchased some medium-plus toast American Oak cubes. Why toasted? It seems most cooperages toast the inside of the barrels prior to charring to bring out more of the vanillans. Next I’m going to blast the cubes with my propane torch until they’re charred. I have zero experience charring oak cubes, so I’m just going to guess how much is enough. There’s quite a few photos of bourbon barrels indicating their level of char. I’ll try my best to replicate that.

The charred oak cubes should be pretty similar to buying a new 5 gallon barrel. The charred oak is going to impart entirely too much flavor into the beer in a very short period of time. After all, we’re trying to replicate a barrel that held whiskey for over a decade. The charred oak loses a lot of it’s ‘essence’ over the years, as the whiskey gets darker and more oaky. So my plan is to soak the charred cubes in un-aged whiskey for at least a month, and then possibly some bourbon for another month. Hopefully that will help leech a good amount of the flavor from the cubes. Will two months of aging the cubes replicate the ten years or more of a traditional barrel? No clue, but there’s only one way to find out.

So that’s about it for now. There will be more posts to follow on this soon. I’m extremely curious if anyone has experience using charred oak in beer. I’ve searched extensively, but that doesn’t mean there isn’t someone out there. Not everything finds it’s way onto the internet =) Also, if anyone has any experience on the oxidation front, I’d love to hear from you as well.

Yes! Thanks for taking on this endeavor. I am eager to see how it turns out… You have motivated me to do a similar type experiment now

Great post! Any chance you'll be posting the recipe for this base beer? And is that a mini fridge? If so, what model?

So for the same reasons as you, Ive experimented with this a bit and strangely enough, using your RIS recipe just bumped up to 1.120. After having my first BCBS a couple years ago, I fell in love with those complex flavors the barrel had contributed. Researching and brewing some near misses ensued until Sometime last year after listening to the Shea comfort podcast on oak in beer (highly recommended!!!) I was able to wrap my head around adding oak in a calculated way. I brewed your RIS recipe, bumped up to 1.120 with 1oz heavy toast American oak cubes in primary. After 3 weeks I transferred to a keg with a new oz of heavy toast American Oak, along with 16oz makers mark.

I've been tasting it monthly along the way leaving the cubes in the whole time. Around the 8-10month mark, things really started to come together. Bourbon, vanilla, Creme brûlée. At 10months I bottled the carbonated beer from the keg, and now 1 year from brew day my mind is blown. I had planned on the oxygen from bottling the beer to help even more to the rounding out The flavors, and it has really done wonders for it.

Anyway, just one guys experience. I think time is very important with these beers, along with the proper use of oak (and some slight oxidation doesn't hurt either) I figured I'd share as your blog really helped me stay with the hobby in my early stages. Now 100+ batches I still reference your recipes from time to time.

Cheers!

I bought some Jack Daniels Smoking Wood Chips once (for smoking).. and they seemed to me authentic (open bag and yep.. Jack Daniels in your face). Some pieces were more charred than others.. I wonder if you could use those.. looks like some people have: http://www.homebrewtalk.com/showthread.php?t=207780

http://www.homebrewtalk.com/showthread.php?t=384390

http://www.beersmith.com/forum/index.php?topic=10921.0

Did you see this? http://www.ebay.com/itm/All-Charred-White-American-Oak-Chips-Distilling-Moonshine-Beer-Wine-Making

Hey Scott! Man… this blog is right in the same alley I'm currently walking down! Like you, I've been putting off making an RIS but I'll be brewing one next. Still trying to script a good solid recipe from recipes I've found online and from friends. BUT… I have brewed a huge barleywine that came in at 1.128 and finished at 1.024. I started with an Abbey 2 yeast and finished with wlp099. the result was great. I then split the 5 gallon batch, kegged and bottled one half and racked the other half into a 3 gallon, glass carboy for aging on actual Bourbon barrel staves! I went looking for a substitute for oak cubes and ran into these very fresh staves that were cut from actual bourbon barrels. they were charred on one side and not the other. so you're actually getting a piece of barrel with the side that was exposed to the elements. I cut off the outside part and threw those staves into the carboy after I resoaked them in bourbon for a few days. they've been sitting in the barleywine for 2 months now. I'll be sneaking a taste in a week to see how it's doing. I found the staves on the Adventures in Homebrewing website. they were $4 + shipping for 2 staves that were approximately 10" in length, 1" wide and 1/8" thick. I threw both into the carboy. I'll check back in with more info. Hope this info was useful.

I'm glad to see this post, Its about up my alley with my current brews. I've currently got some of the american oak spirals char #3 soaking on bourbon for a tribute clone of Black Tuesday. You can find them at farmhousebrewing supply, might make it easier than charring your own. I'm currently thinking that I'll start with 1 and vary my temps while aging, see if that helps pulling the beer in and out of the oak. Theres also a good graphic out there showing temps for toasting and at what levels vanillin is brought out… Looking forward to hearing how yours goes….

Great topic, looking forward to your results. I tried my first crack at oak last January. I only used about an ounce of dark french oak soaked in Jack for a couple of weeks, and then another couple of weeks in the fermenter, this was with a barley wine. It's supposed to age for two years, it's pretty nice already however it's got a little oniony/turnipy thing going on, not sure if that's the french oak or not. I've had some nice bourbon barrel beers before and that's what I was hoping to mimic but not even close.

Yup, the recipe will go up here in about a week or week and a half. I'm just waiting on the beer to finish fermenting out. It's very, very similar to my other Imperial Stout.

That's pretty awesome. I hadn't really heard anyone's experience from leaving the oak in for 6+ months, so it's good to hear it turned out well.

Those are intriguing. Chips work well for short term aging, but not very well for long term. The chips just have too much surface area, and infuse flavor into the beer too quickly.

Some people would see that as a good thing, but i want to sit on this beer for about a year.

I didn't know they were selling actual staves! That's really good info. Thanks!

I didn't know they were selling oak spirals already charred! That might be the way to go.

Another great post. I may try something similar now to enjoy holiday season of next year. Thanks for sharing!

I wrestled over this for a while myself. Then I stumbled across this little gem: http://www.amazon.com/gp/product/B00FBFRWZU?psc=1&redirect=true&ref_=oh_aui_detailpage_o07_s00

Got one of those and I have a FW Parabola clone fermenting in there. So far it's delicious. The barrel was originally filled with Balcones blue corn whiskey ($80+ per bottle). Can't beat it. HMU if you want to discuss.

so when you get the barrel aging to where you are satisfied with it, I have a request (I think I asked before a long time ago). there are several threads on HBT on it.

http://www.homebrewtalk.com/showthread.php?t=358236

http://www.homebrewtalk.com/showthread.php?t=223746

there are clues. I have even tried to do it myself, but so far no one has been able to clone BCS. I would really love to see your take on this, and if we could get this made i'm sure i'm not the only one that would be grateful (it's my second fave beer right behind stone's enjoy and you've already taken care of that for me) 🙂

Do you plan on bottling or kegging this beast?

I'm debating this right now… keg or bottle? Would be nice to be able to pour snifters at a time… Not have to open an entire bottle.

That is pretty handy. How long did you leave the wort in there?

I thought about doing a clone of that, but I kind of wanted a beer I could call my own. I think there's a pretty good clone recipe available from one of the Chicago-based home brew clubs. I think the secret sauce is the aging process though.

Kegging to carbonate, and then I'll bottle about half the batch into bottles.

How would you go about bottling a beer like this? Add in champagne yeast just before bottling?

Made multiple attempts at aging stouts on charred and bourbon soaked oak cubes and never got the depth of oak/spirit character I was looking for until I aged it in a Balcones barrel! First batch stayed in for 6 months and the 2nd went in a month ago, anticipating this one taking at least a year.

So far it's only been in there for about a month or so. I will probably leave it in 3-4 months, or basically until it starts to get warmer around here. Then I will taste it to see if it's ready. I've heard that the beer ages much faster in these small barrels as compared to the 52 gallon barrels breweries are typically using.

How are you keeping it clean before batches? Did you swell the barrel or just put the beer straight in?

Had a batch ready to go when it was delivered and when we transferred the first batch out. Just gave it a quick rinse with boiled water between the two to get some of the trub that had settled out. We swelled it initially by putting it upright and putting a pint or two of boiled water on the barrel head. Been water tight ever since!

Thanks. That's good information. I got mine about a month before I was ready to put beer in it, so I swelled it by filling it with boiling water and letting it sit overnight. Then I poured it out and put a handle of cheap bourbon in it to keep it clean for the month it was going to sit. Every couple of days, I shook it around to coat the interior surface of the barrel with bourbon. When it was time to transfer the beer into it, I dumped the cheap bourbon back into the bottle so I could use it again later. Then I swelled it again by filling it with water and letting it sit in the same cool area under my house where it will sit when the beer is in it. That way it can adjust to the cooler temperature and swell enough to keep it tight while the beer is aging. I poured the water out and racked the beer directly into the barrel from secondary. It's been aging under there for about a month. We've had temperature swings from 20 F to 80F in that time frame and the barrel is still tight. I will probably give it a taste test in the next month or so to see how it's coming along. I would expect to have to leave it in there around 4 months at least.

Did you find that using the smaller 5 gallon barrel allows it to age pretty quickly? In other words, did you taste it before the 6 month mark to see if it had taken on the right flavors yet?

Was actually surprised by how long it took to age, was expecting a much shorter time period. We tasted once a month, but we installed a "Vinnie nail" by drilling a hole in a barrel head and sealing it with a stainless steel nail so that we could sample without exposing the beer to O2.

I had no idea there was someone out there selling this already pre-charred. That might totally be the way to go in the future. I would just want to give it a soak in bourbon for a month or so first.

I'm not really sure. I carbonate in the keg, and bottle from there. You would definitely need to add fresh yeast, I'm just not sure what type.

not sure if this is from the same manufacturer…

http://www.amazon.com/Oak-Infusion-Spiral-Barrel-Bottle/dp/B00QSI6SIG

Hey Scott, I was in Napa last week and caught up with the manager of the barrel aging program at one of the wineries we visited. He's been with the winery for 30 years now and had a TON to say about oak.

– For their best wines (their Estate ones and other small batch expensive ones), they still use traditional barrel aging. For some of their other brands of wines (like 90% of their volume), they simulate their oak aging in big stainless tanks with oak planks.

– In a barrel, the wine only penetrates and contacts 3/16 inch of wood. They have a program where they simulate this with long planks clamped to the bottom of the tanks that are 3/8 inch thick and then do a calculation to find comparable wood surface area to wine volume ratio versus being in a regular barrel.

– Most interesting to me, he used a tube of toothpaste as an analogy for how oak works when I asked about oak spirals. The planks need to be long because the tannins come out the end of the grains, so if you have pieces of wood that are too short you get too many tannins squeezed out. Anything like a chip/cube/spiral will have these short grains.

– They also oxygenate through a .1 micron stone at various rates. The oxygenation is so small that you can’t see bubbles coming out of the stone, and the rates he was talking about were on the order of mL per month in most cases.

– There are different programs they use for different wines and different barrel profiles. He referred to the two wines that we were drinking at the time we caught up with him and said that one uses “Program 16” and the other uses “Program 80”. The difference in programs is the rate of oxygenation and the length of time in the tank.

– Didn’t ask about char on the wood, but obviously his answer here would have been wine-specific and not beer-specific

– Looks like there are a few Micro-Oxygenation vendors online that are probably selling the equipment he’s using. Found this one, and they have some good papers about the process linked from their site http://www.stavin.com/micro-oxygenation

I also had the chance to visit Goose Island's barrel warehouse last month. Imagine a cross between the Willy Wonka Factory and that scene at the end of Raiders of the Lost Ark where they're putting the ark's crate into storage… Re: a comment above about the BCS barrel program, it's pretty simple actually. They source barrels from multiple different bourbon distilleries, don't do ANYTHING to them once they arrive but fill them, and then let it sit for 6 months. They taste each barrel after that and throw out any that have gone bad, set aside any that are super duper good on their own, and then blend the rest.

There are some awesome variants coming out this year, it might be hard for me to resist feeding the AB InBev Machine…

This is all super interesting stuff. The micro-oxygenation setup is definitely a little more in-depth than I'm looking to go.

The grain of the wood is something I really hadn't thought about though. I might have to do some surface area calculations next time and source a single piece of white oak for charring next time.

Yeah, that's micro-oxygenation stuff is pretty in depth, and I think it shows that the rule of thumb for a home brewer is probably "add as little oxygen as possible (greater than 0 oxygen)".

This guy (http://homedistiller.org/forum/viewtopic.php?f=36&t=5602) estimates that a good approximation for contact is 50in^2 oak per gallon. For a 5 gal corny this is 250in^2, but the biggest plank I could probably fit in a ball lock corny is 21×3.5×0.375 inches = 162.75in^2. (I want a 3/8 thick plank because it's double the 3/16 penetration depth). So I'm thinking 2 planks 21×2.6×0.375in gives 250in^2.

I haven't gotten into this part very far, but I found this (http://www.brewgeeks.com/toasted-oak-cubes.html) with an interesting graphic about temp vs oak taste. It's tough to tell what temperature aligns with what, but I think I'd want to be just a bit over 270 degrees F so that Maillard reactions can take place, but not much higher to retain oaky flavors.

So, my starting point will be two planks of 21×3.5×0.375 inches toasted at 275 degrees F for ~3 hours or until I'm happy with the color. No clue on contact time required, but like I mentioned BCBS only needs 6 months…

[…] Here we are, it’s finally time to put my 12% Imperial Stout down for a nice long twelve month nap. To quickly recap, I’m brewing a huge imperial stout, and trying my best to mimic the barrel aging process for the beer. I’ve been wanting to brew a beer like this for a quite a long time, so it feels really good to finally get moving with it. I’ll skip over most of the barrel aging process, as I covered that in my last post. […]

Your blog is exceptional and it has really helped my brewing. In fact you have been instrumental to getting me going as a homebrewer. I jumped in head first with all grain in 2016 and my third beer ever was your Double Jack clone which turned out amazing. And in the years since then I’ve been guided by this blog to brew my high gravity Dogfish 120 clones as well as other high gravity holiday stouts. I know that maintaining a website isn’t easy and life is far more important, but I really hope to see some more from you, whenever you get a chance. In the meantime thanks so much for the great blog.